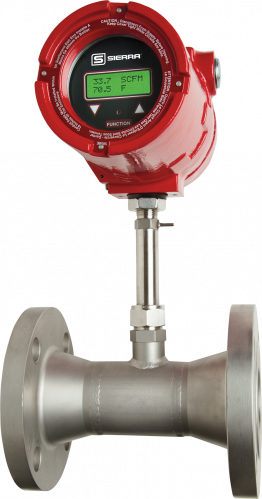

Inline Thermal Mass Flow Meters with Flow Conditioning

FlatTrak™ 780S

- Reduce straight-run requirements with built-in flow conditioning

- Eliminate drift with DrySense sensor

- Needs only 3-diameters up, zero downstream

- Validate in the field for easy in-situ calibration

- Backed by lifetime sensor warranty

Overview

North America's #1 selling inline thermal mass flow meter (2009 Flow Research, Boston MA) delivers precise measurements with heavy-duty industrial gas mass and inline CFM air flow meters. Choose from a wide variety of inline and insertion thermal mass air flow meters for precision CFM (cubic feet per minute) measurement of gas mass flow rate in industrial environments.

Accurate monitoring of peak, low flow and total gas mass flow rates is a critical part of many industrial process control systems. The FlatTrak™ 780S offers improved measurement capabilities in installations where long straight pipe runs are not available. The thermal meter:

- Incorporates Sierra’s unique dual-plate flow conditioning element to eliminate velocity profile distortions, as well as swirl and temperature stratification in the gas stream

- Reduces piping straight run requirements to as little as three upstream diameters

- Saves you money on installation costs when compared to an orifice-plate where at least 20 upstream piping diameters are required for optimal performance

The 780S is GHG certified and routinely used to measure gas to boilers and burners and other process equipment, air volume flow metering, compressed air flow, combustion air flow, natural gas fuel flow, custody transfer and stack gas emissions flow monitoring.Operating Principal: Thermal dispersion technology for direct mass flow measurement featuring no pressure or temperature compensation needed, no moving parts, low pressure drop, high turndown.

Watch the video to learn about Thermal Principle of Operation for thermal mass meters.

Product Benefits

|

|

Specifications

|

|

Go to Autotest Division >

Go to Autotest Division >