Batch Control

Made easy with SmartTrak and Compod

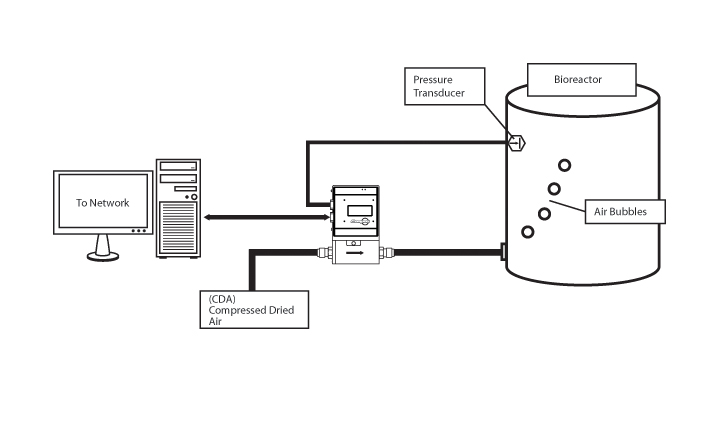

With a SmartTrak mass flow controller upgraded with Compod, batch control is made easy. A pharmaceutical company grows a particular culture in a controlled bioreactor. After the culture is incubated, it is removed to a growth chamber and a new reactor prepared for the next batch. As the batch begins, the reactor chamber is fl ooded with clean, dry air for 1 minute at 10 slpm to make certain it is dry.

Next, the flow rate is reduced to 1 slpm while a culture is injected into the bioreactor. For the next hour, air is injected into the reactor for 30 seconds every 10 minutes at a fl ow rate 5 slpm. This is to aerate the culture and promote homogeneous growth. After the hour is complete, the reactor vessel is transported to the growth area and a new bioreactor takes its place. The cycle resumes.

In this application, Compod is a part of a larger process controlled by a process computer, but it is responsible for managing all the air requirements of the bioreactor during the batch. In addition, the Compod also receives an analog input signal from a pressure transducer inside the reactor vessel. Should the pressure exceed 15 psig, this tranducer sends a signal to the Compod, which stops the flow to prevent breaking the vessel and sends an alarm signal to the master computer.

Go to Autotest Division >

Go to Autotest Division >