d·flux Multiparameter Mass Flow Meter

Multiparameter Mass Flow Meters and Controllers for Gases

- Measure and control five process variables: Mass flow, volumetric flow, temperature, pressure, and density

- High accuracy up to +/-0.3% of user full scale +/-0.5% of measured value

- Five sensor options provide greater flexibility and economy

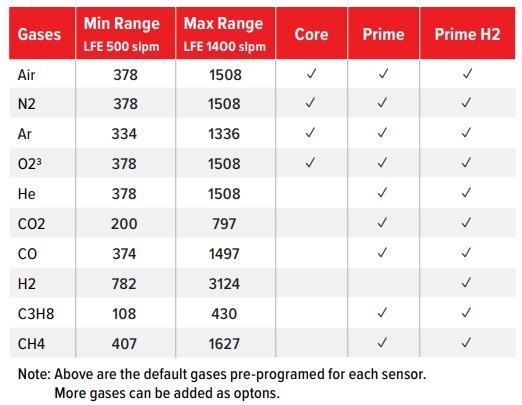

- Multigas Capability: Pre-program up to 15 gases or gas mixtures

- Monitor and control meter functions conveniently from your mobile device with free Android App (Bluetooth)

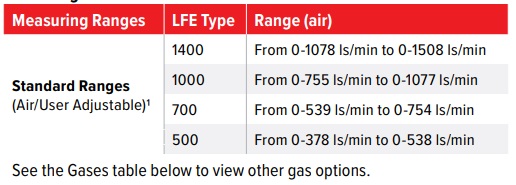

- Flow rates up to 1508 slpm (Air) Other gases, according to conversion, Example: Up to 3120 for Hydrogen

Overview

d·flux High Flow Accuracy Delivers Revolutionary Performance

The demands on scientific and industrial flow measurement instruments have never been greater. Precise measurement of high flows and the ability to make fast and accurate changes between pure gas or gas mixes are crucial. Can you count on the consistent performance of your flow instrumentation in your factory or lab over time? And will your supplier be there for you if the unexpected happens?

With Sierra’s d·flux, you are getting a reliable high-performance package. Carefully milled from stainless steel or aluminum, d·flux is a multiparameter mass flow device that provides precise measurement outputs for five process variables (mass flow, volumetric flow, temperature, pressure, and density). It relies on true physical calculations from advanced 3D polynomial data tables to deliver the flow data you rely on. These diagnostics make switching gases faster and easier, with absolutely no loss in accuracy.

Monitor and Adjust on the Go

d·flux’s user-friendly Bluetooth app, Sierra Flow Connector, is available for free from Google Play. It allows you to easily and securely connect to d·flux with your Android mobile device to create and edit profiles (a set of settings). While operating in the field, you can adjust flow range and dynamic range, filter settings, alarms and warnings, and an assortment of other critical parameters.

Wide Application Scope

d·flux’s proven precision gas control and robust capabilities make it an ideal choice for a wide range of applications including:

- Hydrogen production: Applications include fuel cells, generation, storage and transportation, custody transfer, blending, process monitoring and control

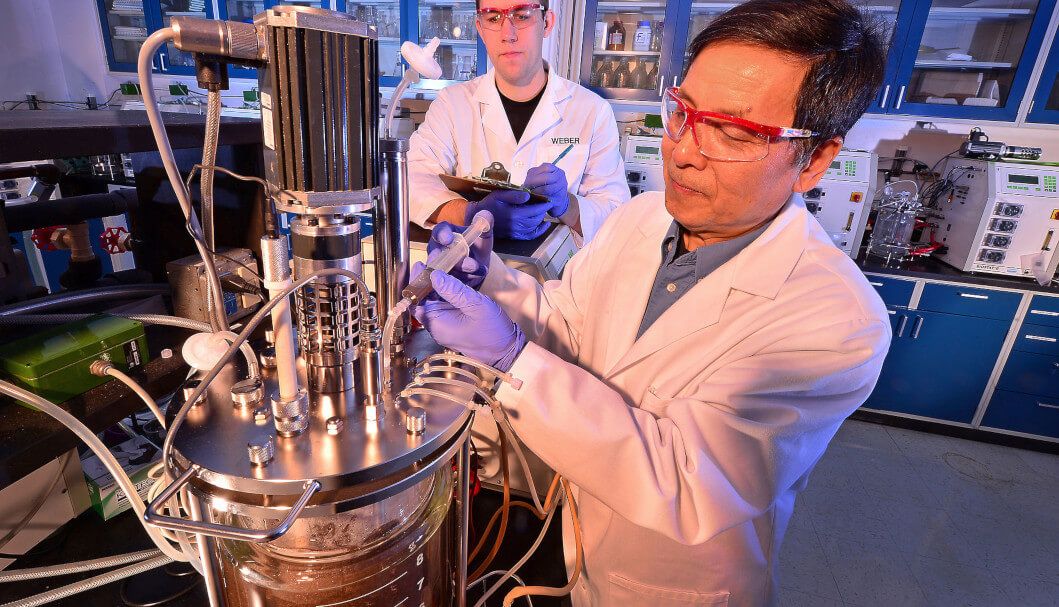

- Biopharmaceutical production: d•flux can be used to culture and grow microorganisms in bioreactors that are later used in medicines, vaccines, and genetic engineering

- Carbon Capture and Storage: Measure the CO2 produced from the burning of fossil fuels or biomass that occurs in chemical bioenergy plants

- Nuclear Energy: Use d•flux to monitor Argon blanketing gas in a welding chamber

- Gas Injection: Measure CO2 used to adjust pH in bioprocessing and wastewater

Sierra Flow Studio

Sierra’s d·flux offers advanced Modbus communication and analog output. Optional digital communications include PROFINET or EtherCAT. Sierra Flow Studio is advanced PC-based software that lets you communicate with your d·flux device in a Microsoft Window’s environment through Modbus. It is available for free download.The Differential Pressure Advantage

Sierra’s d·flux uses a differential pressure measurement over a laminar flow element. The sensors measure the pressure differential, the absolute pressure, and the gas temperature.

With this information, the internal electronics calculate the mass flow going through the device. A unique advantage of the laminar flow meter is its linear relationship between flow rate and developed pressure drop. The meter becomes a mass flow controller by adding a control valve and a PID Controller. You give a setpoint to initiate a repeatable, stable mass flow. Changes to pressure and temperature do not influence the flow rate. Stainless Steel or More Affordable Aluminum Bodies The d·flux Series is available in stainless steel or aluminum flow bodies. The aluminum body significantly reduces the weight and costs of the units while still maintaining excellent specifications and functionality. The anodized aluminum body is compatible with most gases and does not corrode.Sensor Flexibility

d·flux offers a variety of sensor material choices for greater flexibility and economy for a wide range of gas flow applications with exceptional accuracy:- Core Sensor Suitable -Usable with Air, Nitrogen, Argon, and Oxygen gases only, the Core Sensor is a High-Tech Differential pressure sensor. The pressure differential and absolute pressure sensor are embedded in a single modular epoxy-based housing.

A1 Core: ± 0.5% of user full scale ± 1% of measured value - Prime Sensor: Constructed of all SS316L wetted materials, and all wetted parts are stainless. The pressure differential and absolute pressure sensor are integrated in a fully welded stainless housing. It’s tough and highly corrosion resistant. It comes in two options:

- B1 Prime: +/-0.3% of user full scale +/-0.7% of measured value

- B2 Prime: Prime high accuracy +/-0.3% of user full scale +/-0.5% of measured value

- Prime Hydrogen Sensor – The Prime Hydrogen Sensor is the same as the Prime sensor but has a gold coating on the membrane. This makes the sensor suitable for H2 applications (H2 permeates through 316 membranes). It is also available as a high-performance sensor with optimized accuracy.

- B3 Prime H2: +/-0.3% of user full scale +/-0.7% of measured value

- B4 Prime H2 high accuracy: +/-0.3% of user full scale of measured value

Note: User full scale = ~70…100% standard range

Product Benefits

- One device measures and controls five process variables: mass flow, volumetric flow, temperature, pressure, and density

- Flow rates up to 1508 slpm (Air)

- Other gases, according to conversion, Example: Up to 3120 for Hydrogen

- High Accuracy – Up to +/-0.3% of user full scale and +/-0.5% of measured value

- Multigas Capability – Pre-program 15 gases and/or gas mixes

- Monitor and control meter functions conveniently from your mobile device with free Sierra Flow Connector App

- Available in Stainless Stell or Aluminum Bodies

- Cost effective- 5 sensor options to meet your budget:

- Core sensor (economical solution) for air, nitrogen, oxygen, and argon.

- Prime Sensor suitable for all gases (2 versions available)

- Gold-plated Prime sensor – ideal for hydrogen (2 versions available)

- Digital Communications: Advanced Modbus and analog output. PROFINET or EtherCAT available as options

- Minimize uncertainty with Autotare – dflux controllers detect with an advanced algorithm when there is no flow and then automatically zero (tare) for optimal performance.

- Custom Application Profiles – Get up to 15 application profiles with d·flux – allows storage of individual application details. Each profile has an individual totalizer

- Sierra Flow Studio Software – Communicate with d·flux in Microsoft Windows environment through Modbus

Specifications

- Multiparameter Measurement and Control (mass flow, volumetric flow, temperature, pressure, and density)

- Accuracy (5 Sensor options)

- A1 Core: ± 0.5% of user full scale ± 1% of measured value

- B1 Prime: ± 0.3% of user full scale ± 0.7% of measured value

- B2 Prime high accuracy: ± 0.3% of user full scale ± 0.5% of measured value

For Hydrogen applications: - B3 Prime H2: ± 0.3% of user full scale ± 0.7% of measured value

- B4 Prime H2 high accuracy: ± 0.3% of user full scale ± 0.5% of measured value User full scale = ~70…100% standard range

- Sensor Options:

- Core sensor: suitable for air, nitrogen, oxygen and argon. Only with FKM and EPDM.

- Prime sensor: suitable for all gases excluding H2. Available with FKM, EPDM and FFKM

- Prime H2 sensor: suitable for all gases including H2 (gold coated sensor) Only with FKM and EPDM

Note: All sensors are available with both aluminum and stainless-steel bodies. Prime sensors are also available with a high accuracy option

- Sensor Stability: Less than 0.2% of measured value/year after tare

- Repeatability: ± 0.2% of factory full scale

- Flow ranges: up to 1508 slpm (Air)

- Other gases according to conversion (ex. Up to 3124 slpm for hydrogen)

- Pressure: 1 to 200 psia (1 to 14 bar a)

- Response time:

- Meter: 120 msec

- Controller: 2000 msec

Update time mass flow value: 10 msec Sensor sample rate: 1 msec. / 4 msec. with optimized filter settings

- Warm-up Time: <2 seconds for full accuracy

- Turndown (Dynamic Range):1:100 for most gases; 1:1000 with Automated Dynamics: (meter only)

Automated or a fixed dynamic range can be selected during order process. This setting can be changed anytime using the Sierra Flow Connector App. - Note: The dynamic range is gas and pressure dependent, higher pressures means lower dynamic range.3

- Operation Pressure: 1 to 200 psia (1 to 14 bar a)

View All Specs (datasheet) |

|

Documents & Downloads

Datasheets(2) | |||

| File Title | Version | Release Date | |

|---|---|---|---|

d·flux Multiparameter Technical Datasheet | A | 01/31/2025 | |

d·flux Safety Information Sheet | A | 01/31/2025 | |

Manuals(1) | |||

| File Title | Version | Release Date | |

d·flux Multiparameter Instruction Manual | V2.1.A | 02/03/2025 | |

Guides(4) | |||

| File Title | Version | Release Date | |

Accessory Guide: d·flux Multiparameter Series | A | 06/04/2025 | |

Accessory Guide: Tri-Clamp Fittings | V2 | 06/04/2025 | |

d·flux Mulitparameter Series Gas List | V1 | 01/31/2025 | |

d·flux Multiparameter Quick Start Guide | V1 | 06/04/2025 | |

Software(5) | |||

| File Title | Version | Release Date | |

d·flux Multiparameter Sereis Driver for RS485 to USB Converter | 01/31/2025 | ||

d·flux Multiparameter Series Profinet GSDML Files | 01/31/2025 | ||

d·flux Multiparameter Service Tool | 1.0.8 | 01/31/2025 | |

Sierra Flow Connector App | 1.8.4 | 01/31/2025 | |

Sierra Flow Studio | 1.0.4 | 01/31/2025 | |

Certificates(2) | |||

| File Title | Version | Release Date | |

d·flux Multiparameter Declaration of Conformity | 01/31/2025 | ||

d·flux Multiparameter UKCA Delcaration of Conformity | 01/31/2025 | ||

Go to Autotest Division >

Go to Autotest Division >