Mass Flow Meters for Industrial Applications

Attain Accurate Measurements with Precise Mass Gas Flow Meters

For over 40 years, Sierra’s flagship line of thermal mass flow meters has provided customers with precise and repeatable gas mass flow meter measurements in the most demanding industrial gas mass and air mass flow measurement applications. Our gas mass flow meters feature the long-term stability of our patented no-drift DrySense velocity sensor technology backed by a lifetime warranty. The result of DrySense is maximum sensitivity, reproducibility, immunity to cracking and shifting over time, and ultimately greatly improved accuracy.

See the chart below for selecting the best thermal mass flow meter for your industrial application. Also visit the high-performance QuadraTherm Thermal selection chart for higher accuracy requirements, highest flow range capability and multivariable outputs.

Our Construction Provides Precise Gas Mass Flow Meter Readings

All Sierra industrial thermal mass flow meter products utilize “Immersible Thermal” sensing technology and are widely used for precise mass flow meter gas measurement. Rugged and reliable, our line of gas mass flow meters are work horses in the industry and are commonly used to measure air and natural gas, as well as all other industrial gases and mixtures.

We want to help you pick the right gas mass flow meter or controller for your application. See our complete listing of mass flow meters and controllers or request a quote today. A local expert will contact you to discuss your application. You can also try our live help function to get in touch with one of our expert applications engineers immediately.

|

Thermal Mass Flow Meters for Gases (Two-Sensor Design)

|

||

|---|---|---|

|

Greater than

6" |

>>> (Virtually Unlimited Max Flow Rate)

|

|

|

6"

|

||

|

4"

|

||

|

3"

|

||

|

2"

|

||

|

1.5"

|

||

|

1"

|

||

|

0.75"

|

||

|

0.5"

|

||

|

0.25"

|

||

|

||

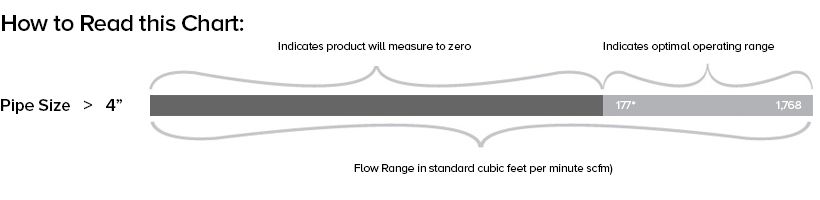

Ranges shown are optimal minimum/maximum ranges for air.

Meters will read to zero flow with decreasing accuracy.

Maximum mass velocity 20,000 sfpm

Flow rates based on ANSI schedule 40 pipe

100:1 turndown

Go to Autotest Division >

Go to Autotest Division >