High Performance Industrial Thermal Mass Flow Meter

PowerMass TM500™

- Accuracy

- +/- 1.0% of reading plus +/- 0.2% of full-scale – Air, Nitrogen

- +/- 1.5% of reading plus +/- 0.5% of full-scale – All other gases

- Repeatability +/- 0.2% of full scale

- Direct measurement of gas mass flow / No volume to mass calculations

- DigiSense™ robust sensor design

- AC or DC power

- Use optional Gas-Mix™ feature to easily change gas selection or create gas mixes in the field - no recal required

- 2-3 week delivery lead times / 1 week delivery possible

Overview

Built to Tell the Truth.Whether you're a facilities manager or a process, energy, or environmental engineer, the questions are the same. Are the flow measurements you're getting for your system accurate and reliable? How quickly can you make necessary adjustments in the field that you can depend on?

The Sierra PowerMass TM500 promises precision, speed, and the field flexibility you need to adjust gas mixes and configure meter settings to maintain optimum process efficiency. Designed for the most demanding industrial processes in facilities management, chemical plants, gas refineries, and petrochemical production, Sierra flow measurement instruments are built to last and meet your application, budget, and delivery needs.

The PowerMass TM500 makes you smarter and your processes more reliably efficient. And we're always here if you need us—Sierra's promise to customers for 50 years.

Why Thermal?

Sierra's thermal technology delivers direct measurement of gas mass flow. Unlike differential pressure (dP) meters that measure volumetric flow, it’s simpler to make and maintain, and no temperature or pressure corrections are required. dP requires additional calculations to convert volumetric flow to mass flow, the measurement that most often needs to be reported. That reduces accuracy. Thermal has negligible pressure drop or flow restrictions, significantly reducing expense once the full ownership cost is considered.

DigiSense™ SensorDigiSense is the state-of-the-art sensor technology used in the TM500. Unlike other thermal flow sensors, it interfaces directly with its microprocessor for greater control, precision, and programmability. DigiSense accurately responds to changes in process variables (gas flow rate, pressure, and temperature) to determine mass flow rate, totalized flow, and temperature.

DigiSense’s correlation algorithms allow the meter to be calibrated on a single gas in the factory while enabling the user to select other gases in the Gas-Mix menu.

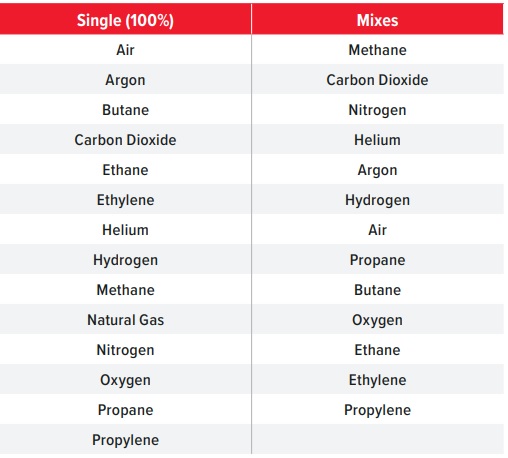

Gas-Mix™ MenuGas-Mix allows users rapid gas selection or mixing in the field from a pre-calibrated list of 14 gases. With an onboard 2-line x 16-character backlit display, operators can view flow rate, total, elapsed time, process gas temperature, and alarms. The display is also used with the configuration panel to access flow meter settings, such as 4-20mA and pulse output scaling, pipe diameter, low flow cutoff, flow filtering (damping), display options, and high or low alarm limits.

TM500-View SoftwareSierra's TM500-View advanced software is a free PC-compatible application available for download from Sierra's website. Connect your Windows-based laptop or PC to the meter using the USB port interface to access meter data and configure the meter’s settings.

View Features- Get quick access to all configuration parameters with pop-up windows and pull-down menus

- View raw data to diagnose or troubleshoot your meter

- Select measurement units, flow and temperature ranges, alarm settings, and more

- Print or save a TM-Cal Calibration Validation Certificate

- Set alarms and display alarm codes

- Use simulation mode to align 4-20mA output with the input to the user’s PLC/DCS

The PowerMass TM500 includes on-board calibration verification through the TM-Cal feature. This diagnostic is automated and does not require any additional equipment or removal of the TM500 from process. TM-Cal takes less than five minutes for completion and can be initiated via the meter’s display, Modbus RTU, or TM500-View software. When the test is complete, a pass/fail response indicates if the meter requires troubleshooting or recalibration.

Using TM500-View to run TM-Cal results in a calibration validation certificate, it can be printed or saved for compliance with the user’s local regulations and metrology requirements. The certificate is encrypted and includes all relevant information from the test: time and date, meter identification, and pass/fail results.

Measurably Different™Our primary goal at Sierra is to help make your operation smarter and more productive with the precision flow measurement tools we design and build to meet your application, budget, and delivery needs. And with 50 years of expertise, we're always here for you.

Product Benefits

PRECISION- Accuracy

- +/- 1.0% of reading plus +/- 0.2% of full-scale – Air, Nitrogen

- +/- 1.5% of reading plus +/- 0.5% of full-scale – All other gases

- Repeatability +/- 0.2% of full scale

- Direct measurement of gas mass flow / No volume to mass calculations

- DigiSense™ robust sensor design

- Welded, 316 SS sensor

- Insertion, Inline, and Remote styles

- Rotatable enclosure: allows ±180 degree display orientation

- AC and DC

- Velocity Range: 0 to 45,000 sfpm

- Wide measurement range: up to 1000:1 turndown; 100:1 typical

- Negligible pressure drop

- Two 4-20mA outputs for flow rate and temperature

- Measure gas flow rate in scfm, mcfd, kg/h, and more

- Low-end sensitivity (0-500 sfpm) for leak detection and other low-flow applications

- Communication options: HART or Modbus RTU (RS485)

- FM/FMc, ATEX, IECEx, and UKEX approvals

- NEMA 4X and CE Mark

- Microprocessor based, field programmable electronics

- Menu of field selectable gas compositions with Gas-Mix™

- Free TM500-View™ software available / USB port connects to a PC

- Calibration Validation with TM-Cal™

- NIST-traceable calibration

- 2 to 3 week lead times are typical after order acceptance

- 1 week expedited lead times are available after order acceptance

- Contact Sierra for details

Specifications

NOTE: For accuracy +/-0.5% to 0.75% of reading above 50% of full scale - See QuadraTherm)

|

|

Documents & Downloads

Datasheets(2) | |||

| File Title | Version | Release Date | |

|---|---|---|---|

TM500 Technical Datasheet | C | 11/19/2025 | |

FlowTrak Datatsheet for BioTrak 645i, 645S, TM100, and TM500 | B | 01/22/2025 | |

Manuals(2) | |||

| File Title | Version | Release Date | |

TM500 Instruction Manual | C | 07/17/2025 | |

TM500-View Software Instruction Manual | A | 11/29/2023 | |

Guides(2) | |||

| File Title | Version | Release Date | |

Instructions for Welding NPT Female Branch Outlet to Pipe | A | 11/08/2023 | |

FlowTrak Quick Install Guide for BioTrak, TM100, andTM500 Series | A | 02/15/2024 | |

Software(2) | |||

| File Title | Version | Release Date | |

VCP Driver (for TM500-View Software) | 1.0 | 11/11/2024 | |

TM500-View Software | 3.3.1 | 12/03/2024 | |

Certificates(12) | |||

| File Title | Version | Release Date | |

TM500 FM ATEX Certificate | FM23ATEX0042X | 04/25/2025 | |

TM500 FM Certificate (Canada) | FM21CA0090X_4.25 | 04/25/2025 | |

TM500 FM Certificate (UK) | FM23UKEX0041X | 04/25/2025 | |

TM500 FM Certificate (USA) | FM21US0124X_4.25 | 04/25/2025 | |

TM500 IECEx Certificate of Conformity | 23.0020X_002 | 04/25/2025 | |

CRN Approval (Alberta) | 4.8.34 | 10/29/2024 | |

CRN Approval (British Columbia) | 4.8.34 | 10/29/2024 | |

CRN Approval (Manitoba) | 4.8.34 | 10/29/2024 | |

CRN Approval (Multi-Province) | 4.26.24 | 10/30/2024 | |

CRN Approval (Ontario) | 4.8.34 | 10/29/2024 | |

CRN Approval (Quebec) | 4.8.34 | 10/29/2024 | |

CRN Approval (Saskatchewan) | 4.8.34 | 10/29/2024 | |

Additional Documentation(1) | |||

| File Title | Version | Release Date | |

Industrial Flow Meter Catalog | V1 | 11/19/2025 | |