Santa Cruz Wastewater Treatment Facility, located in Santa Cruz, California, generates the majority of its own electric power by using internal combustion engines that burn a mixture of methane gas produced by the sewage digestion process and purchased natural gas. Combined, they producing 7.4 million kWh of electric power per year.

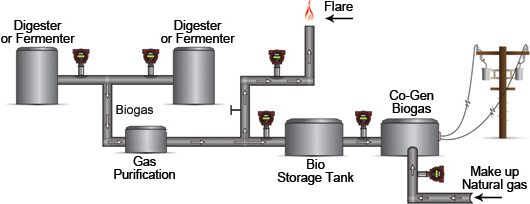

Producing abundant, healthy amounts of biogas each day in their digesters is the cornerstone of Santa Cruz Wastewater's unique renewable energy program. Acting like a large stomach, the solids from the treatment process are "digested" in four large domed digesters and heated to 98 degrees. When methane forming bacteria break down the acids in the digester, large amounts of anaerobic digester gas, made up of 60% methane and 40% CO2 are produced. Once cleaned, compressed and mixed with natural gas, this biogas becomes a valuable fuel for the plan's co-generators, which produce enough electricity to meet over 50% of the plant's electrical needs.

SIERRA'S SOLUTION

By 2007, Santa Cruz Wastewater, had replaced all of its meters with Sierra's SteelMass® 640S and FlatTrak™ 780S immersible thermal mass flow meters to achieve the increased accuracy they required for cogeneration. Sierra's design features an insertion probe with two small diameter sensors to measure gas temperature and velocity and nominal pressure drop.

Digester gas is produced at low flow rates, so meters that can measure very low flows are required. Low flows create a very small differential pressure across a differential pressure (dP) device such as an orifice plate or annubar, so the flow signal often becomes lost in the noise of the measurement. The high turndown (100:1) provided by the 640S and 780S overcomes the inherent limitations of dP. With Sierra's thermal technology, Santa Cruz Wastewater can measure true mass flow directly with outstanding rangeability at virtually no pressure drop.

With accurate biogas measurements and gas blending for cogeneration, the 640S and 780S have helped Santa Cruz Wastewater become a flagship renewable energy facility. By reusing its methane, Santa Cruz Wastewater prevents 41 tons of CO2 emissions per year from polluting our atmosphere, and through the cogeneration process the facility can supplement its energy supply. Operators like Mike Meyers of Santa Cruz Wastewater make energy saving decisions every day. "The bottom line for us is power," Meyers said. "It's an energy savings balancing act."

Here's what makes the Sierra's 640S and 780S an ideal choice:

- Measures mass flow directly with one meter

- 100:1 turndown for accurate monitoring of peak and low flow situations

- In-line flow conditioning eliminates piping straight-run requirements

- Removable probe for easy cleaning

- Generates minimal pressure drop across the instrument

Go to Autotest Division >

Go to Autotest Division > DOWNLOAD

DOWNLOAD